Why Milk Paint's Matte Finish Beats Polyurethane

A wood finish influences both the tactile experience and the long-term evolution of a piece. Woodworkers who compare a table coated with polyurethane to one treated with milk paint notice a profound difference that extends past mere coloration. The milk-painted surface appears soft, natural, and integrated with the material. Polyurethane, however, imparts a glossy, impermeable quality. Increasing numbers of woodworkers select milk paint to emphasize the inherent texture of wood while avoiding the artificial plastic sheen associated with polyurethane.

The Appeal of a Natural Matte Finish

Milk paint has served furniture and cabinetry makers for generations due to its ability to produce a finish that retains the sensation of wood. This paint derives from milk protein, lime, and natural pigments, which integrate directly into the wood fibers. Such composition allows subtle grain patterns to remain visible.

The resulting surface possesses a velvety quality and scatters light rather than mirroring it. This effect creates visual depth akin to that found in antique furnishings. Woodworkers replicate this aesthetic on contemporary projects through the application of two thin coats, followed by sealing with wax or hemp oil. The outcome yields a permeable layer resistant to cracking or peeling amid wood movement.

Key advantages:

- The matte quality conceals minor imperfections like dents and scratches.

- Chemical bonding occurs with wood fibers for deeper integration.

- Refreshing requires minimal effort, without full sanding.

Woodworkers who prioritize the genuine character of wood grain benefit from milk paint's organic presentation, free from polyurethane's contrived gloss.

Cost and Budget Comparison

One quart of milk paint powder ranges from $25 to $35 and covers 75 to 100 square feet after mixing with water. Polyurethane similarly costs $20 to $40 per quart, yet demands three complete coats for uniformity. Brushes, sandpaper, and extended drying periods bring the overall expenses of both options into alignment for modest undertakings.

Budget considerations by project scale:

- Small furniture pieces (under 20 square feet): Materials total $10 to $20.

- Cabinet sets (60 to 100 square feet): Expect $60 to $90 for milk paint or $80 to $120 for polyurethane.

- Full-room trim or paneling: Costs reach $150 to $250 for milk paint, varying with application thickness and sealant selection.

Milk paint often proves more economical in preparation and maintenance. Cleanup involves only water, and it emits no strong odors, enabling indoor work without specialized equipment like spray booths or respirators.

DIY or Professional Application

Milk paint stands out as an accessible option for do-it-yourself enthusiasts. Prepare it by combining equal volumes of powder and water, then strain the mixture for even consistency. Use a natural bristle brush or foam roller for application; it dries rapidly and levels itself during curing. The desired rustic patina emerges naturally from manual techniques rather than mechanical spraying.

Step-by-step DIY guide:

- Prepare the surface by cleaning and lightly sanding.

- Mix batches in small quantities to ensure uniform results.

- Brush on two thin coats, allowing approximately 30 minutes between applications.

- Apply wax, oil, or a compatible topcoat to enhance protection.

Polyurethane application calls for precise environmental control, including ample ventilation, dust-free conditions, and exact coat intervals. Excessive thickness leads to bubbles or streaks. Homeowners frequently engage professionals for extensive work, incurring additional fees of $3 to $5 per square foot.

For novice or small-scale woodworkers, milk paint provides an easier entry point and enhanced opportunities for personalization.

Living with Your Finish

The decision to use milk paint over polyurethane affects daily engagement with the wood piece. Its matte surface encourages handling and appears serene under ambient lighting. Dust accumulates less noticeably, and it eliminates the distracting reflections common to glossy finishes.

Users describe milk-painted items as vibrant because they patina elegantly over time. Scratches integrate seamlessly rather than disrupting the appearance. This resilience suits high-use items such as chairs, dressers, or built-in cabinetry, simplifying upkeep.

For those desiring added cleanliness or a contemporary edge, apply a light water-based varnish over milk paint. This preserves the subdued sheen while boosting longevity. Professionals often employ milk paint as a foundational layer in high-end productions for its versatility.

Resources and Visual Aids

Recommended visuals:

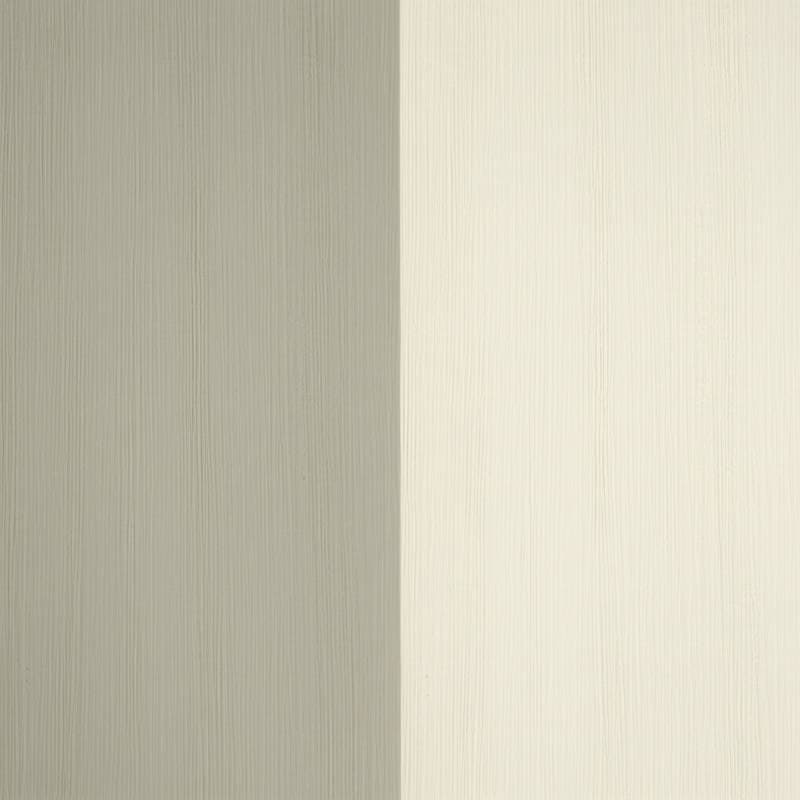

- Figure 1: Comparative board displaying milk paint and polyurethane under natural illumination.

- Figure 2: Illustrated sequence for mixing and sealing milk paint.

Alt text purpose: Highlight texture differences and application steps to assist readers in selecting natural wood finishes.

Enhancing Wood Projects with Milk Paint

Milk paint elevates woodworking by preserving the material's authenticity and inviting ongoing interaction. Its sustainable composition and straightforward use align with modern preferences for eco-conscious craftsmanship. Woodworkers achieve enduring beauty through this finish, transforming routine projects into cherished heirlooms.